Video Measurement Systems <---

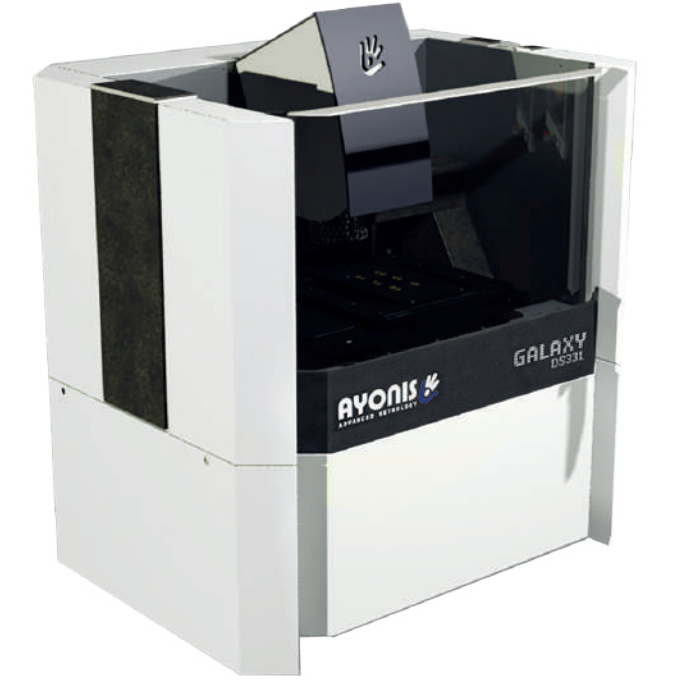

GALAXY DS 331

2D and 3D metrology for small parts.

Different measuring means gathered into an automated one.

Designed for control in production environment.

Offline programming (from CAD files).

Recording and statistical analysis of measurements to optimize traceability and quality control.

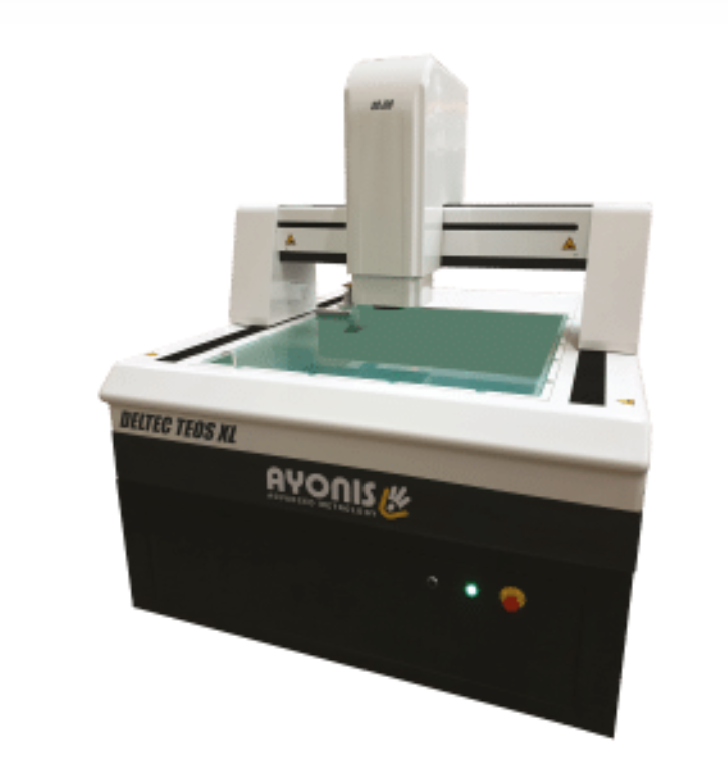

Machine Structure

• Solid granite structure.

• High precision cross-motion XY table with linear motors.

• XYZ (upper / lower) measuring range: 300 x 300 x 100 / 50 mm.

• Metrological structure isolated by antivibration pads.

• Structure compatible with a production environment.

• Load capacity: 20 kg.

• Encoder resolution: 3 nm.

• X, Y speed: up to 200 mm/s (depending on configuration).

Main measurement sensor:

• Line sensor based on Confocal Chromatic technology (white light sensor).

• Single or double sided.

• Up to 350 000 measuring points per second and per side.

• 2 types of sensors to fit your needs (high accuracy / high capacity).

Secondary measuring sensor:

• High resolution digital camera 5, 20 or 71 MPX

• Mono or multi-field configuration

• Programmable lighting devices:

o Episcopic red sectored LED

o Diascopic LED collimated green

Uncertainties of measurement (2σ):

• XY: from 2.5 µm

• Z height (1 side): from 0.5 µm

• Z thickness (2 sides): from 1.0 µm